by

Dr. Richard Bonner

In the rapidly evolving world of data centers, cooling technology stands at the intersection of innovation and necessity. With the increasing demand for processing power, particularly for AI and machine learning workloads, traditional cooling methods are being stretched to their limits. Two-phase liquid cooling is emerging as a game-changing solution, offering enhanced cooling performance along with energy efficiency and sustainability benefits. This post explores why two-phase cooling is superior to traditional methods and examines the safety and efficacy of the dielectric coolant used in these systems.

Why is Two-Phase Liquid Cooling a Superior Cooling Method?

Superior Heat Removal Through Phase Change

Two-phase cooling operates on the principle of phase change, wherein a coolant transitions from liquid to gas as it absorbs heat. This phase change is what sets two-phase cooling apart from single-phase methods, in which the coolant remains in the same liquid state throughout the process.

In single-phase cooling systems, commonly found in water- or oil-based setups, the coolant absorbs heat as it flows over a given heat source, like the CPUs or GPUs in a server. However, the efficiency of this process, otherwise known as sensible heating, is limited. As the coolant heats up, its ability to absorb more heat decreases, making the system less efficient over time.

In contrast, two-phase cooling leverages the energy required for the coolant to change from liquid to gas. During this transition, bubbles form on the cold plate surface, enhancing its cooling efficacy by increasing mixing and convective heat transfer. This process enables the system to extract more heat at the same temperature difference, which allows servers to operate more efficiently while maintaining lower and more consistent chip temperatures.

Efficiency in Flow Rate and Temperature Uniformity

One of the significant advantages of two-phase cooling is that it can operate at lower flow rates while still removing the same amount of heat. This is particularly beneficial in reducing the overall energy consumption of the cooling system. The boiling process in two-phase cooling also ensures that the coolant maintains a constant temperature across the cold plate, which is crucial for modern chips with varying thermal loads.

The benefits extend to performance as well. For example, in tests with NVIDIA’s H100 GPUs, two-phase cooling kept chip temperatures below 57°C, compared to 66-71°C with single-phase water cooling. This not only prevents performance throttling but also opens up possibilities for overclocking and extending hardware lifespans. As chip manufacturers design future generations with two-phase cooling in mind, this method will become even more critical for handling the high-power densities and heat fluxes of tomorrow’s workloads.

Environmental and Resource Efficiency

Two-phase cooling systems are more than just efficient in terms of heat transfer; they also offer significant energy and water savings. Traditional cooling methods, particularly those relying on whole-room air conditioning, can consume vast amounts of energy and water. The current consensus is that data center’s consume between 1-1.5% of all global energy use (more than the UK’s entire annual energy production). Furthermore, analysts agree with the math that suggest that nearly half of that electricity is used for data center cooling alone. In terms of water consumption, data centers are amongst the top-ten water-consuming industrial or commercial industries in the US. In contrast, two-phase systems utilization of a dielectric refrigerant minimizes the need for water and allows its cooling processes to operate at much higher efficiencies – both in terms of facility water required (if any at all) and in terms of the energy required to cool high-powered chips – reducing the overall environmental footprint of data centers.

Is The Refrigerant Safe? What about PFAS?

Choosing the Right Coolant: Performance and Sustainability

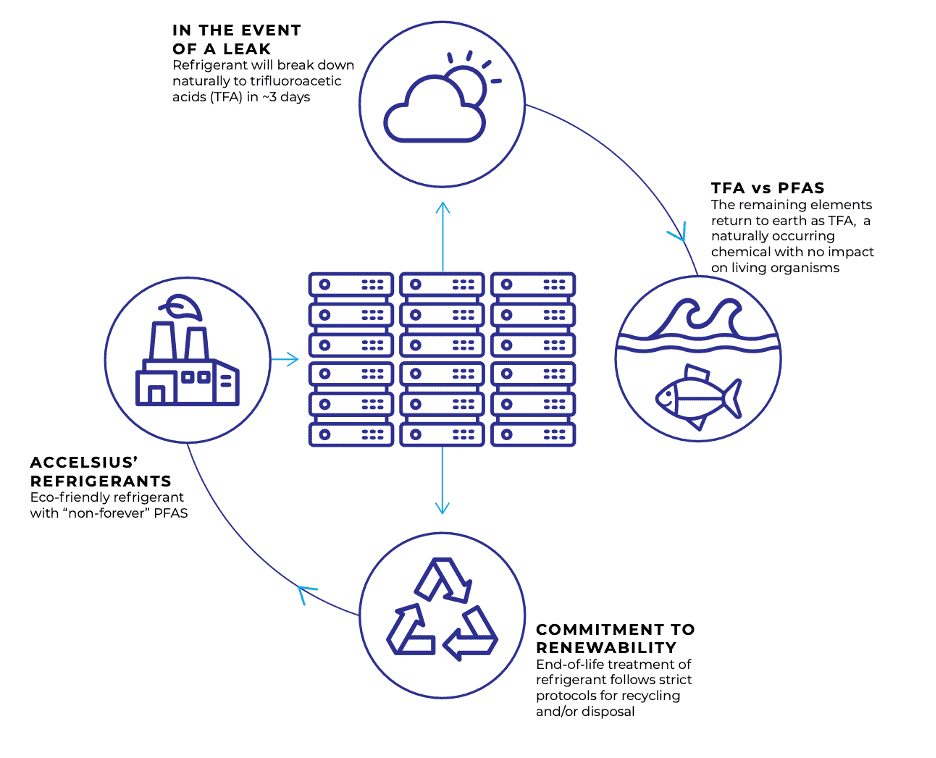

Selecting the right coolant for two-phase cooling systems is about balancing performance with safety and sustainability. With these considerations in mind, R1233zd, a fourth-generation refrigerant, has become our top choice. One of the standout characteristics of R1233zd is its low global warming potential (GWP) of 1, making it significantly more environmentally friendly than older refrigerants, which often belong to the broader category of polyfluoroalkyl substances (PFAS). PFAS chemicals have been criticized for their potential environmental hazards, particularly their persistence in the environment, earning them the nickname “forever chemicals.” However, R1233zd is designed to break down quickly in the atmosphere into trifluoroacetic acid (TFA), a naturally occurring compound that poses minimal environmental risk.

Addressing Environmental and Health Concerns

It’s important to understand that PFAS refers to a broad category of chemicals with vastly different properties. The solid forms of PFAS, which can contaminate water supplies and accumulate in living organisms, have contributed to the negative perception of these substances. However, the refrigerants used in two-phase cooling systems, like R1233zd, are in a different category. These refrigerants are designed to have minimal environmental impact when properly managed. For example, in the rare event of a refrigerant leak, R1233zd quickly vaporizes and breaks down into benign byproducts long before reaching the stratosphere, where our ozone exists.

Regulatory Oversight and Future Considerations

Regulatory bodies worldwide are increasingly focusing on the environmental impact of refrigerants, but they also recognize the critical role these substances play in enabling efficient data center cooling. For instance, proposed European legislation allows for the continued use of certain refrigerants in data centers, acknowledging their importance in maintaining both performance and sustainability. By following best practices and adhering to regulations, data centers can continue to use refrigerants like R1233zd responsibly, minimizing their impact on the environment while reaping the benefits of two-phase cooling.

The Future of Data Center Cooling

Two-phase liquid cooling is more than just a new technology; it is a critical advancement in data center thermal management. With its superior heat transfer capabilities, energy and water efficiency, and environmentally friendly dielectric refrigerants, it offers a compelling solution for the challenges faced by modern data centers. As chip manufacturers continue to push the boundaries of performance, two-phase cooling will become an essential tool for meeting the demands of tomorrow’s computing power.

By embracing two-phase cooling, data centers can achieve higher efficiency, lower environmental impact, and improved performance—ensuring they remain at the cutting edge of technology while contributing to a more sustainable future.